A Major Milestone in the Build Process

Written by Christoph, 07. January 2026

The Seafoiler project has reached a significant construction milestone.

The hull has now been fully reinforced with bulkheads and stringers, creating a highly stiff, weight-optimized structure and marking readiness for the critical mating of hull and deck.

Thanks to exceptionally precise engineering and execution, we were able to reduce bonding material by approximately 50 kilograms—a substantial achievement in lightweight construction and a direct contributor to performance, efficiency, and overall sailing dynamics.

In parallel, all secondary molds have been completed. These enable the production of key components such as the bowsprit, roof structures, hatches, and additional custom composite parts. This marks an important step toward full systems integration and serial component accuracy.

Every phase of the build follows a strict design-to-weight philosophy, combining advanced composite materials, high-quality prepreg laminates, and meticulous craftsmanship. The result is a yacht engineered without compromise—where structural integrity, minimal mass, and performance are perfectly aligned.

Seafoiler stands for the next generation of high-performance sailing:

lighter, stiffer, faster—and engineered with purpose.

We’re delighted that the hull moulds have been produced to such an exceptional standard, achieving a gloss level of over 97 GU in mold manufacturing – an outstanding result.

Next, the deck mould will be completed, while in parallel, the first hull will be built using unidirectional carbon fibre prepregs, a 20 mm foam core, and cured under high pressure and heat.

The Seafoiler 35 project continues to evolve — with major progress in carbon prepreg manufacturing and composite optimization.

Our newly developed adjustable oven has been built, tested, and fine-tuned to deliver higher heating performance and precisely controlled ventilation, ensuring perfectly uniform curing of all prepreg components.

In parallel, we’ve tested multiple prepreg laminate configurations and improved the protective films for easier and cleaner handling during layup. Following successful trials, full prepreg production has now started.

Our composite team has expanded, with new specialists trained in continuous fiber layups — a key technique that reduces fiber overlaps and optimizes load paths within the carbon structure.

The outcome:

-

Further weight reduction through the elimination of unnecessary overlaps

-

More uniform surface finish, requiring less fairing and sanding

-

Improved structural efficiency across the entire hull

Each step brings us closer to our goal — building one of the lightest and most efficient high-performance carbon monohulls in its class.

Production Kick-Off: Tooling Begins for the Seafoiler 35

Written by Christoph, 04. June 2025

With the official production start on June 1st, the manufacturing of the Seafoiler 35 has entered a new phase: the beginning of the tooling process.

The positive molds for the components are built on rigid steel frames. First, XPS is applied and CNC-milled, then coated with fiberglass and resin, and layered with PU modeling paste – followed by another round of CNC machining to achieve maximum precision. This process results in highly accurate master models that serve as the basis for the later composite production.

Through several sanding and filling cycles, the molds are further refined with various materials depending on specific requirements. The goal: a flawless surface finish for the subsequent laminate construction – from hull to cockpit, from foil case to deckhouse.

The Seafoiler isn’t just striking in appearance – it’s a masterpiece of engineering. Its speed, lightness, and stiffness come from advanced aerospace-inspired construction using carbon fiber, epoxy resin, and prepregs.

A Structure with Purpose

The hull, deck, and foils are built entirely from unidirectional carbon fibers, laid precisely in the direction of load paths. This ensures every fiber works at maximum efficiency – delivering exceptional stiffness at the lowest possible weight.

Resin, Reinvented

Instead of traditional hand layup, the Seafoiler uses prepregs – pre-impregnated carbon fibers with a precisely calibrated amount of epoxy resin. This results in a perfect fiber-to-resin ratio, giving the structure both lightness and superior mechanical properties.

High-Tech Core

The foils and hull are constructed in a high-performance sandwich design: a lightweight foam core is enclosed between carbon skins. Just like an I-beam, this structure offers excellent rigidity with minimal mass – ideal for high-speed sailing.

The Result: Technology That Flies

The Seafoiler applies cutting-edge materials and techniques inspired by aerospace and Formula 1 – tailored for life offshore. The result is a boat that not only flies across the water, but sets new standards in construction.

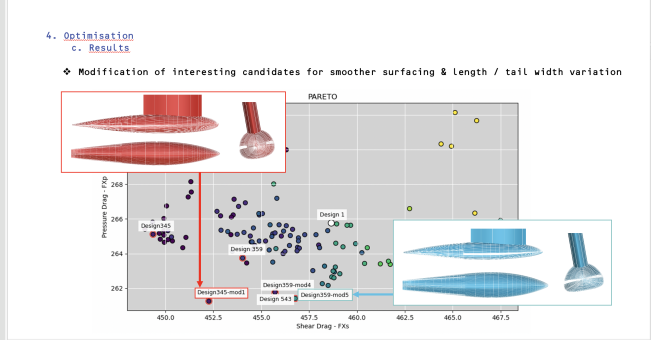

The optimization aimed to strike the best possible balance between low forward drag force (FX) and high lateral lift force (FY). Simulations considered two representative sailing conditions derived from the Velocity Prediction Program (VPP): a light wind condition at 5.3 knots with high leeway angle, and a high-speed condition at 20.8 knots.

Simulation & Design Space

The bulb geometry was controlled via 24 parameters, including top and bottom curves as well as the side profile. Over 600 design variants were generated, with 130 of them evaluated through high-resolution CFD simulations (25 million cells). A custom optimization loop automatically assessed objective functions while ensuring compliance with strict constraints: maximum length of 2.2 meters, projected area, and minimum inertia at three defined cross sections.

Round or Sharp Leading Edge?

The analysis revealed clear differences: a round leading edge delayed the transition to turbulence, reducing shear drag, while a sharp nose reduced pressure drag. Further refinements, including smoother surface transitions and variations in length and tail width, ultimately led to the selection of an optimal design.

Result: A Bulb That Delivers

The selected bulb design combines minimal drag with maximum lateral lift — while

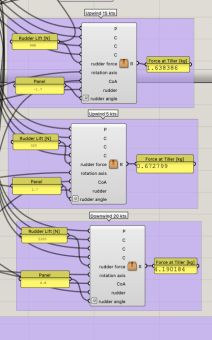

Tomas from D3 Applied tech optimizes the rudder geometry for different speeds and an ideal steering feel. After numerous simulations, we decided on the following settings:

-

Upwind 5 knots: 0.67 kg

-

Upwind 15 knots: 1.63 kg

-

Upwind 20 knots: 4.1 kg

In addition, we define hole positions that allow for different steering characteristics to be adjusted according to the helmsman's preferences.

In our weekly meeting, we were presented with the latest simulation results – and the computers at D3 Tech were running hot.

The team investigated whether the Seafoiler, equipped with additional rudder foils, would be even more stable – and potentially faster – in moderate sea conditions at 20 knots of true wind speed. The simulations were run using the weight of the Luxury Racer (LR). Two configurations – the green and the blue hull – went head-to-head. The outcome: a clear tie.

Our conclusion? When the boat is perfectly balanced, rudder foils aren’t necessary. That’s great news – it allows us to offer our clients a less complex, more user-friendly boat with the added benefit of lower costs.

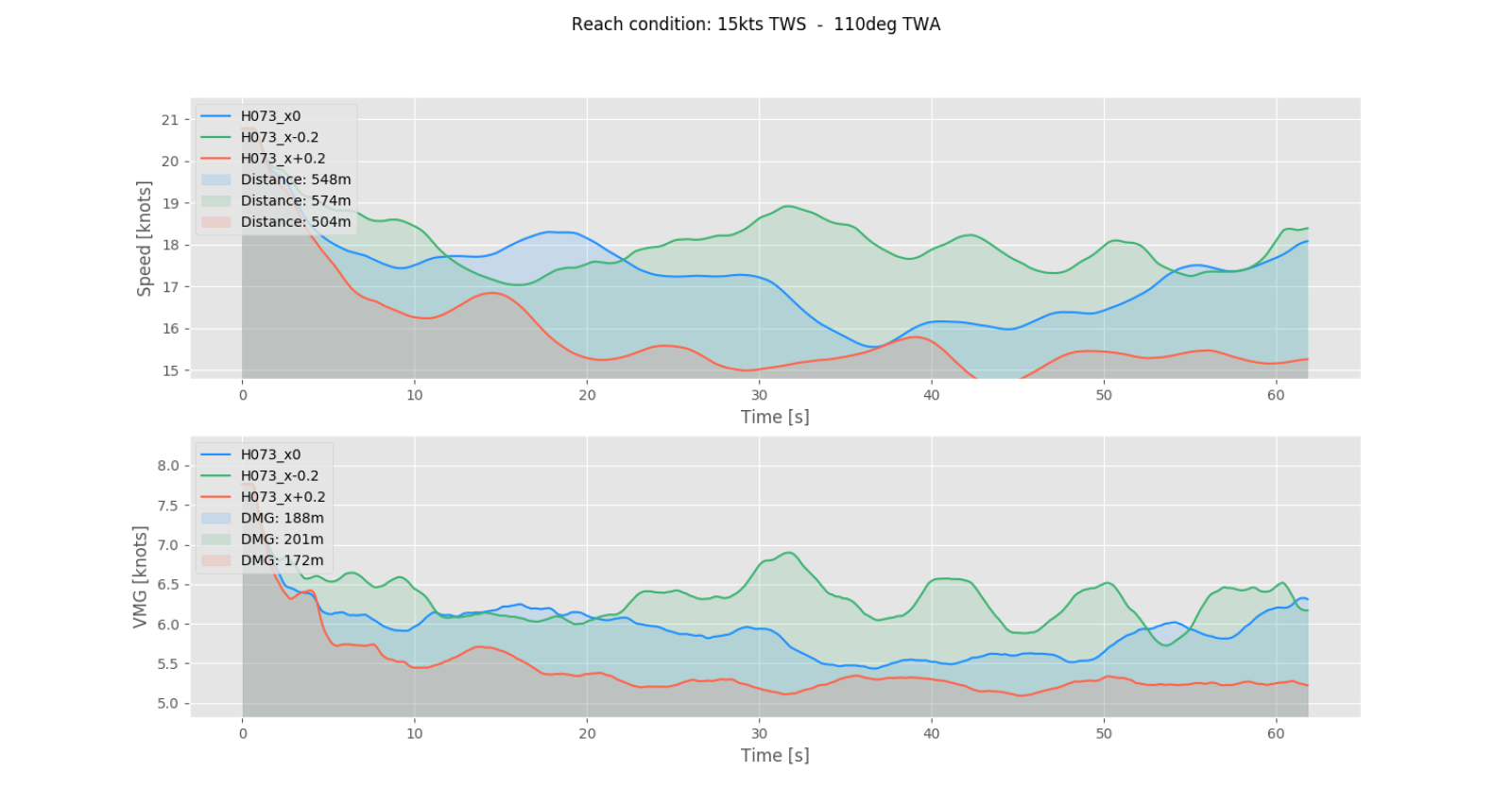

How much difference can 20 centimeters make? Quite a lot, as our latest simulations with the Seafoiler 35 clearly demonstrate.

Under steady reaching conditions (15 knots true wind speed, 110° true wind angle), we tested three foil positions: the baseline configuration (x0), as well as variants with the foil moved 20 cm forward (x–0.2) and 20 cm aft (x+0.2).

The verdict is clear: shifting the foil forward (x–0.2) consistently delivered the highest average speed and the most effective Velocity Made Good (VMG). With over 574 meters sailed in 60 seconds and a VMG-corrected distance of 201 meters, this setup marks the new benchmark for efficient reaching performance.

These tests confirm what every performance sailor knows: even minor adjustments to foil geometry can lead to measurable gains in speed, balance, and directional efficiency. A key milestone on the road to finalizing the Seafoiler 35’s optimized foil layout.

Today, Gonzalo and his team from D3 Applied Technologies are presenting the exciting results of an intensive optimization phase. At the center of their work: the precise alignment of foil and keel positions to perfectly balance the Seafoiler at 20 knots of true wind speed and moderate sea state.

This is not only a milestone in performance development – it’s the starting point for a new round of targeted innovation. We’re looking forward to the next steps in this pioneering project.

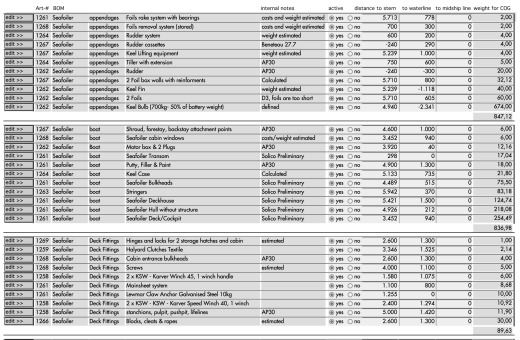

Hans from Aeomar has updated the weight list. Every single screw is meticulously positioned with its distance from the stem and the waterline. We need this information to balance the center of gravity (COG). Only based on this data can accurate simulations be performed. I’m very grateful to Hans for taking on this time-consuming but extremely important task on behalf of all of us.

Speed has always fascinated sailors. From ancient wind powered vessels to today’s high tech designs, the pursuit of faster, smoother and more efficient sailing never stops. But what if your next boat didn’t just cut through the water- what if it could rise above it?

Many sailing enthusiasts wonder when it’s the right time to buy hydrofoil boat technology that blends speed with comfort. The Seafoiler-35- answers that question with precision.

Designed through world-class engineering and built for both adventure and ease this hydrofoil monohull represents a new era in performance sailing.

Whether you crave offshore racing or smooth weekend cruising, the Seafoiler-35- gives you the freedom to experience sailing like never before.

Why Buy Hydrofoil Boat?

Hydrofoiling has shifted from being an exclusive racing technology to a practical solution for sailors who are seeking speed, efficiency and stability. When you buy a hydrofoil boat like the Seafoiler-35-, you gain performance that traditional monohulls cannot match. Once the foils lift the hull clear of the water, drag drops dramatically, giving you higher speeds, quicker acceleration and a smoother ride in choppy conditions.

Even when not fully foil-borne, the foils can improve stability while sailing, significantly reducing heel because the leeward foil provides righting moment and helps keep the boat upright.

This is not just about going fast. It is about making sailing more comfortable, more efficient and more rewarding. And as demand for innovative sailing experiences grows investing in hydrofoil technology today means stepping into the future of marine design before the rest of the world catches up.

Built for Speed: Performance That Redefines Sailing

The First Monohull Foiler of Its Kind

The Seafoiler-35- stands in a category of its own. It is the world’s first monohull foiler that balances speed, stability, and safety. Engineered by Swissroof GmbH in collaboration with leading experts such as the renowned D3 Applied Technologies, it brings proven America’s Cup innovation to recreational and competitive sailing.

Top Speeds Over 25 Knots

Thanks to its two powerful C-foils and ultra-light carbon construction, the Seafoiler-35- reaches speeds exceeding 25 knots. Every detail, from the foil geometry to the aerodynamic rig, is designed to help the boat rise early and fly efficiently.

Precision Through Advanced Engineering

The Seafoiler uses prepreg carbon fiber, a technology also found in aerospace and Formula 1. This ensures remarkable stiffness, low weight, and superior strength. The result is an agile boat that transforms wind power into pure performance with minimal drag.

Stability and Safety: A Boat You Can Trust

Exceptional Righting Moment

The adjustable foils generate a powerful righting moment, providing stability even in strong winds. This makes the Seafoiler-35- suitable for both offshore adventures and competitive regattas.

CE-Certified for Offshore Sailing

With CE Category B certification, the Seafoiler-35- is built for open-sea sailing. The boat meets strict ISO standards that ensure safety, structural reliability, and durability under challenging conditions.

Balanced Steering System

After numerous simulations, the rudder geometry was optimized for smooth steering at different speeds. Whether cruising at 5 knots or flying at 20, you enjoy consistent, predictable handling.

Comfort Meets Performance: Designed for Real Life

Even with its advanced engineering, the Seafoiler-35- is not only a racing machine. It’s built with real sailing lifestyles in mind.

Smart Interior Layout

You get sleeping space for five, a compact galley, a high-quality shower, and an electric toilet (in the Luxury Racer model). After hours of high-speed sailing, comfort becomes just as important as performance.

Standing Headroom

Unlike many performance boats, the Seafoiler-35- offers generous standing room. This makes moving inside the cabin easier and more enjoyable.

Lightweight Yet Durable

Weighing only 1.9 metric tons, the boat focuses on efficiency and lift without compromising structural strength. Every component from foils to deck uses carefully crafted carbon prepreg construction for durability and precision.

Easy Handling: Made for Solo and Family Sailing

Single-Handed Sailing Made Simple

Developed by experienced solo sailors, the Seafoiler-35- handles smoothly even in challenging conditions. The layout is designed for intuitive control, making it ideal for single-handed sailing or small crews.

Raise the Mast Alone

You can raise the mast independently and quickly. This gives you greater freedom—no waiting for crane slots or marina staff.

Trailerable and Slipway-Ready

With a beam of 2.55 m and total weight under 3.5 tons, the Seafoiler-35- complies with EU transport regulations. You can move it without special permits. Slipway launching is easy, saving time and eliminating the need for expensive marina cranes.

Performance Options for Every Sailor

Team Racer (TR)

A lightweight, pure-performance model made entirely from carbon prepreg. Ideal for racing teams or sailors who want maximum speed with minimal equipment.

Luxury Racer (LR)

Everything from the TR model, plus added comforts:

-

Master cabin

-

Aft cabin

-

Full galley

-

Electric toilet with warm shower

-

Detailed interior finishes

The LR version maintains the same high performance, just with enhanced onboard comfort.

Real Engineering Progress: Built With Purpose

Precise, High-Quality Construction

The Seafoiler-35- is built using CNC-milled molds, advanced carbon laminates, and optimized hull forms. Every stage from foil placement studies to bulb shape simulations, aims to improve efficiency and deliver maximum lift with minimal drag.

Racing-Level Optimization

CFD simulations, velocity prediction programs, and structural analyses ensure the final design meets the highest competitive standards. Even 20-centimeter adjustments in foil position were tested to find the perfect layout for maximum VMG.

Ready for the Future

With sea trials beginning in 2026, early buyers will experience a boat shaped by years of research, modeling, and testing. It’s not just a product, it’s a breakthrough in monohull hydrofoil design.

Why You Should Buy the Seafoiler-35- Now

When you choose to buy hydrofoil boat like the Seafoiler-35-, you're investing in:

-

Future-proof sailing technology

-

A high-speed, low-drag experience

-

Offshore safety and stability

-

Flexible handling for solo or family trips

-

Eco-friendly, electric-supported navigation

-

Comfort without compromising performance

Hydrofoil sailing is growing fast. Early adopters enjoy a clear competitive edge, more excitement on the water, and far more efficient travel. With pre-orders open and limited availability, now is the best time to secure your place in the next chapter of high-speed sailing.

Conclusion

The Seafoiler-35- is more than a boat. It’s a new level of freedom on the water. Whether you want to race, cruise, or explore, this hydrofoil monohull delivers top performance, unmatched stability, and practical comfort in one advanced design. If you’re ready to experience sailing that truly flies, reach out today and take your first step toward owning a Seafoiler.

Ready to learn more? Contact Seafoiler and secure your pre-order now.

Speed has always been a great fascination for sailors. The feeling of being lifted above the water and slicing through the wind is a kind of excitement that is difficult to express. With the evolution of technology, that feeling gets even more intense. Hydrofoils not only speed up sailing but also make it smoother and more efficient

The number of sailors looking for a hydrofoil sailing boat for sale has increased today because they desire the new performance level that is more thrilling than ever before. Be a racer, an adventurer or a casual sailor, you will always get to enjoy a different world on the water with hydrofoil boats.

They bring together the attributes of power, precision, and comfort to give one amazing experience. If you are planning the upgrade of your sailing adventure this is indeed the perfect time.

Why Choosing a Hydrofoil Sailing Boat for Sale Is a Smart Move

Hydrofoil boats have changed modern sailing. These boats rise above the water as speed increases. This reduces drag and increases stability. As a result, sailors enjoy faster speeds with less effort. Many buyers look for a hydrofoil sailing boat for sale to enjoy offshore adventures, racing events, or smooth coastal cruising.

Hydrofoils also bring a sense of control. They cut through waves instead of slamming into them. This makes the ride more stable and more enjoyable. It also reduces fatigue during long journeys.

Hydrofoils are not only about performance. They also enhance the overall sailing experience. When the foils are engaged while sailing, the leeward foil generates additional righting moment, which keeps the boat noticeably more upright. This typically limits heel to around 6 degrees, resulting in a more stable, comfortable, and controlled ride even in changing wind and wave conditions.

Understanding the Technology Behind Hydrofoils

Hydrofoil sailing uses underwater wings called foils. As the boat gains speed, these foils create lift. This lift raises the hull above the water. Once the hull is up, the boat experiences less drag and more control.

Modern hydrofoils incorporate modern materials such as carbon fiber. These materials possess the characteristics of being strong, light and long-lasting. Thus, they enable the designers to create boats with high speed, good stability and safety as well as excellent performance in a wide range of conditions.

Smart engineering is also a part of hydrofoil boats. Adjustable foils help sailors fine-tune stability. Twin rudder systems improve steering. Lifting keels help with shallow waters and easy transport. Electric propulsion adds sustainable power. All these features create a smooth, efficient experience for every sailor.

The Seafoiler -35-: A New Generation of Monohull Foiling

If you are searching for a high-performing hydrofoil sailing boat for sale, the new Seafoiler -35- sets a new benchmark. It is the world’s first monohull foiler that blends exceptional speed with comfort and offshore capability.

Designed with expertise from Swissroof GmbH and D3 Applied Technologies, the Seafoiler -35- achieves top speeds of more than 25 knots. This makes it one of the fastest foiling monohulls in its class. Yet it remains stable, safe, and easy to handle.

Key Dimensions and Specs

- Length Overall: 10.5 m

- Beam Overall: 3 m

- Displacement: TR 1695 kg / LR 1980 kg

- Ballast: 700 kg

- Draught: 0.5 m (min) / 2.5 m (max)

- Air Draught Max: 16.55 m

- Energy Capacity: 7–14 kWh

- Max Engine Power: 8 kW

These features make the Seafoiler -35- fast, efficient, and easy to transport.

Built to Fly: How the Seafoiler -35- Stands Out

The Seafoiler -35- is engineered for performance. Every detail supports speed, stability, and safety.

Exceptional Stability

Two adjustable high-performance foils create the righting moment. This gives the boat steady control even in strong winds.

Speed When It Matters

The foils and lightweight prepreg carbon construction allow speeds beyond 20 knots. For racers or adventure sailors, this is perfect.

Easy Transport and Shallow-Water Access

With a draft of just 0.5 m when raised, the boat works well in many environments. It launches easily from a slipway. No crane is needed. It is trailer-friendly and complies with EU width and weight standards.

Ready for Offshore Journeys

The Seafoiler -35- meets World Sailing Design Category B. This means it is suitable for offshore conditions and longer trips.

Comfort Meets Performance: Inside the Seafoiler -35-

Many people think hydrofoil boats only focus on speed. But the Seafoiler -35- also delivers comfort and practicality.

Sleeping for Five

The interior includes a master cabin, aft cabin, and saloon. This makes it perfect for small families or regatta crews.

Functional Galley

A refrigerator, stove, and storage make life on board easy.

Bathroom and Shower

Longer journeys become more comfortable with a proper toilet and warm-water shower.

Standing Room

Extra headroom gives you freedom to move and relax.

These thoughtful features make the Seafoiler -35- more than a technical marvel. It becomes a real home on the water.

Performance Options for Every Sailor

The Seafoiler -35- comes in two versions:

Team Racing (TR) Version

- Lightweight full carbon prepreg construction

- Two C-foils

- Full carbon rig

- Twin rudder system

- Lifting keel

- 1 day of training

- 24-month warranty

This option is perfect for sailors who want pure performance with minimal extras.

Luxurious Racing (LR) Version

- All TR features

- Master cabin

- Full galley

- Aft cabin

- Electric toilet and warm shower

- Carbon or wood interior finishes

This version suits sailors who want the best mix of speed and comfort.

Finding the Right Hydrofoil Sailing Boat for Sale

Before choosing a boat consider the following:

1. Purpose

Do you want to race? Cruise? Explore? Or all three? A boat like the Seafoiler -35- works well for many activities.

2. Skill Level

Modern foilers are easier to handle than older versions. Adjustable foils and advanced rudder systems help even less experienced sailors.

3. Transport and Storage

If you want to move the boat often, check trailer compatibility and width regulations. The Seafoiler -35- is built for easy transport.

4. Safety Standards

Look for CE certifications and ISO compliance. These show the boat is safe for offshore trips.

5. Sustainability

Electric propulsion and hydrogeneration systems support eco-friendly sailing.

6. Comfort Needs

If you plan longer journeys, cabins, galley space, and headroom become important.

When comparing any hydrofoil sailing boat for sale, always look at both performance and practical features. The best boat gives you speed without losing comfort.

Where to Experience the Seafoiler -35-

Sea trials begin in 2026 in Switzerland. Later, exclusive trial weeks will be held in:

- Genoa

- Barcelona

- Les Sables-d’Olonne

Sailors who want a hydrofoil sailing boat for sale can test the Seafoiler-35- with expert guidance. Day test sails even include training and refreshments. The fee is deducted from the purchase price if you decide to buy.

Wrapping Up

Hydrofoil sailing is not anymore only for top athletes. It is going to be available, effective, and comfortable more than ever. In case you are searching for a fast, stable, and adventurous experience, then the hydrofoil sailing boat for sale is the best way to enhance your sailing experience.

The Seafoiler -35- integrates the latest design, off-sea ability, and considerate comfort into one splendid vessel. To explore this innovation and start your journey toward high-speed sailing, connect with Seafoiler today.